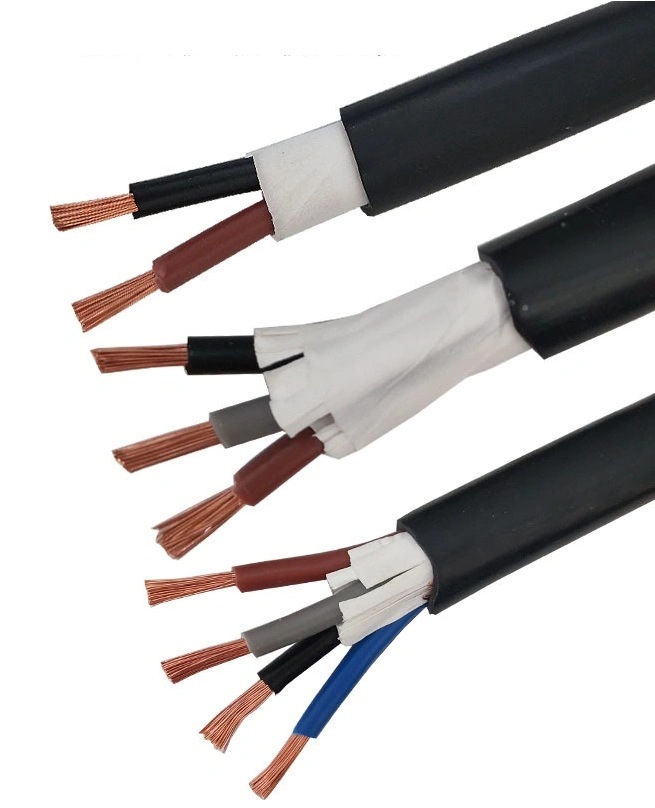

Our Multicore PVC Cables include:

Multicore Solid Cable

Multicore Flexible Cable

Multicore High Flexible Cable

Multicore Solid Cable

Flexible Unshielded Cable

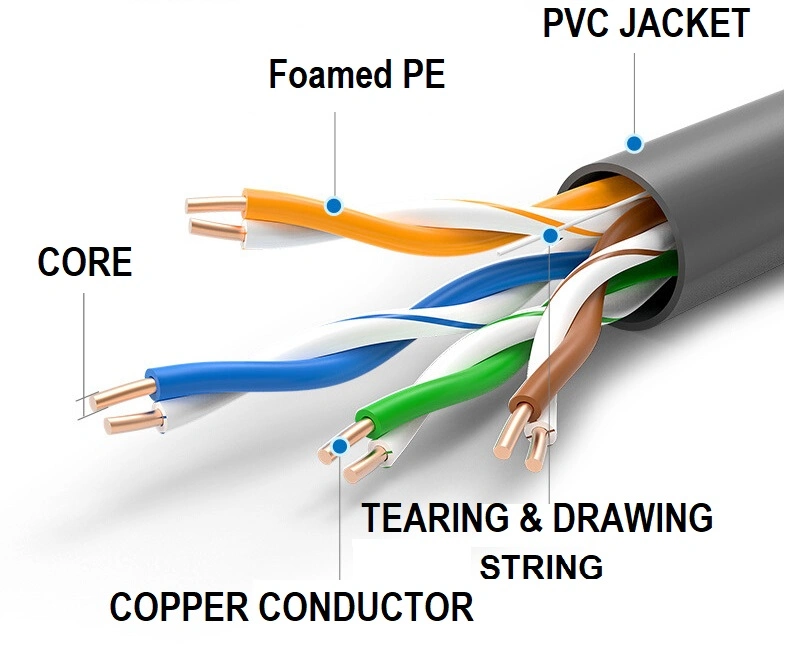

A multicore cable is a type of electrical cable that combines multiple signals or power feeds into a single jacketed cable. The term is normally only used in relation to a cable that has more cores than commonly encountered. Not all cables with multiple insulated conductors are called multicore cables - the core in multicore refers to the number of usable connections made, not the number of conductors or wires. In most cases, a "usable connection" requires multiple conductors, such as the positive and negative conductors used for DC power.

Cutaway diagram of a shielded multicore cable with four cores each with three individual conductors

For example, a standard three-conductor mains cable is never referred to as multicore, but a cable comprising four coaxial cables in a single sheath would be considered multicore. Confusingly, the term multicore is occasionally used to refer to the number of individual conductors rather than the number of connections, especially in Europe. A cable with multiple conductors, but not a multicore cable, is usually called a multi-conductor or multi-wire cable.

| Our Multicore PVC Cables include: Socapex Cable Multicore Flexible Cable Multicore High Flexible Cable Multicore Solid Cable Flexible Unshielded Cable |

Soncapex Cable

|

APPLICATIONS:

Our highly flexible multicore Socapex cable is widely used in the connection of lighting technology and dimmer racks in events of all types around the world. This range is suitable for use in dry and damp environment. With its PVC sheathing, it is also designed to withstand moderate mechanical stress and UV exposure when used outdoors.

Socapex cables can be used in free and fixed applications with a voltage rating of 300/500V.

| Part Number | Number of Cores | Nominal Cross- Sectional Area | Maximum Overall Diameter mm |

| A5Y19015 | 19 | 1.5mm2 | 18.2 |

| A5Y19025 | 19 | 2.5mm2 | 21.62 |

| Conductor | Flexible Copper (Class 5) |

| Insulation | Polyvinyl chloride (PVC) Type TI1 |

| Outer Sheath | Polyvinyl Chloride (PVC) Type TM2 |

Multicore Flexible Cable

|

| Description | Multicore Flexible Cable |

| Conductor: | Stranded Copper Conductor of Class 5/6 (Flexible) |

| Insulation: | PVC Compound |

| Insulation Color | Red, Blue, Grey, Yellow/Green or as request |

| Sheath | PVC Compound |

| Sheath Color | White, Black |

| Temperature Range: | -30 - 70ºC |

| Nominal Voltage: | 300/500V, 450/750 V |

| Test Voltage: | 2000 V |

| Minimal Bending Radius: | 4D for D < 8 mm 5D for 8 - 12 mm 6D for D > 12 |

| Standard | IEC 60227 |

| Cross-section | Conductor Construction | External diameter | Insulation thickness | Sheath thickness | Conductor resistance at 20 °C | Insulation resistance at 70°C | Cu weight | Cable weight |

| nominal | min-max. | nominal | nominal | max. | min. | |||

| mm² | n x mm | mm | mm | mm | Ω/km | MΩkm | kg/km | kg/km |

| 2 x 0,75 | 24 x 0,20 | 5,7 - 07,2 | 0,6 | 0,8 | 26,0 | 0,011 | 14,4 | 52 |

| 2 x 1 | 32 x 0,20 | 5,9 - 07,5 | 0,6 | 0,8 | 19,5 | 0,010 | 19,2 | 65 |

| 2 x 1,5 | 30 x 0,25 | 6,8 - 08,6 | 0,7 | 0,8 | 13,3 | 0,010 | 28,8 | 90 |

| 2 x 2,5 | 50 x 0,25 | 8,4 - 10,6 | 0,8 | 1,0 | 7,98 | 0,0095 | 48,0 | 115 |

| 3G0,75 | 24 x 0,20 | 6,0 - 07,6 | 0,6 | 0,8 | 26,0 | 0,011 | 21,6 | 70 |

| 3G1 | 32 x 0,20 | 6,3 - 08,0 | 0,6 | 0,8 | 19,5 | 0,010 | 28,8 | 80 |

| 3G1,5 | 30 x 0,25 | 7,4 - 09,4 | 0,7 | 0,9 | 13,3 | 0,010 | 43,2 | 115 |

| 3G2,5 | 50 x 0,25 | 9,2 - 11,4 | 0,8 | 1,1 | 7,98 | 0,0095 | 72,0 | 175 |

| 3G4 | 56 x 0,30 | 10,5 - 13,1 | 0,8 | 1,2 | 4,95 | 0,0078 | 115,2 | 235 |

| 4G0,75 | 24 x 0,20 | 6,6 - 08,3 | 0,6 | 0,8 | 26,0 | 0,011 | 28,8 | 75 |

| 4G1 | 32 x 0,20 | 7,1 - 09,0 | 0,6 | 0,9 | 19,5 | 0,010 | 38,4 | 92 |

| 4G1,5 | 30 x 0,25 | 8,4 - 10,5 | 0,7 | 1,0 | 13,3 | 0,010 | 57,6 | 145 |

| 4G2,5 | 50 x 0,25 | 10,1 - 12,5 | 0,8 | 1,1 | 7,98 | 0,0095 | 96,0 | 210 |

| 4G4 | 56 x 0,30 | 11,5 - 14,3 | 0,8 | 1,2 | 4,95 | 0,0078 | 153,6 | 299 |

| 4G6 | 84 x 0,30 | 14,7 | - | - | 3,30 | 0,0068 | 230,4 | 480 |

| 5G0,75 | 24 x 0,20 | 7,4 - 9,3 | 0,6 | 0,9 | 26,0 | 0,011 | 36,0 | 96 |

| 5G1 | 32 x 0,20 | 7,8 - 9,8 | 0,6 | 0,9 | 19,5 | 0,010 | 48,0 | 113 |

| 5G1,5 | 30 x 0,25 | 9,3 - 11,6 | 0,7 | 1,1 | 13,3 | 0,010 | 72,0 | 175 |

| 5G2,5 | 50 x 0,25 | 11,2 - 13,9 | 0,8 | 1,2 | 7,98 | 0,0095 | 120,0 | 260 |

| 5G4 | 56 x 0,30 | 13,0 - 16,1 | 0,8 | 1,4 | 4,95 | 0,0078 | 192,0 | 363 |

| 5G6 | 84 x 0,30 | 16,7 | - | - | 3,30 | 0,0068 | 288,0 | 583 |

| 7G1 | 32 x 0,20 | 09,0 | 0,6 | - | 19,5 | 0,010 | 67,2 | 136 |

| 7G1,5 | 30 x 0,25 | 10,6 | 0,7 | - | 13,3 | 0,010 | 100,8 | 195 |

| 7G2,5 | 50 x 0,25 | 13,0 | 0,8 | - | 7,98 | 0,0095 | 168,0 | 294 |

ApplicationThis product is suitable to be used in household appliances such as washing machines, spin dryers and refrigerators, electric tools and lighting in home , office and similar indoor place where need flexible wire.

Multicore High Flexible Cable

|

| Description | Multicore High Flexible Cable | |||||||

| Conductor: | Stranded Copper Conductor of Class 5/6 (Flexible) | |||||||

| Insulation: | PVC Compound | |||||||

| Insulation Color | Red, Blue, Grey, Yellow/Green or as request | |||||||

| Sheath | PVC Compound | |||||||

| Sheath Color | Black | |||||||

| Temperature Range | -30 - 60ºC | |||||||

| Nominal Voltage | 300/500V | |||||||

| Test Voltage | 2000 V | |||||||

| Minimal Bending Radius | 7.5D | |||||||

| Standard | IEC 60332 | |||||||

| cross-section | Conductor Construction | Conductor diameter | Insulation thickness | Sheath thickness | External diameter | Conductor resistance at 20 °C | Cu weight | Cable weight |

| nominal | max. | nominal | nominal | min-max. | max. | approx. | ||

| N x mm² | n x mm | mm | mm | mm | mm | Ω/km | kg/km | kg/km |

| 1 x 1,5 | 30 x 0,25 | 1,8 | 0,8 | 1,4 | 5,7 - 7,1 | 13,3 | 14,4 | 57 |

| 1 x 2,5 | 50 x 0,25 | 2,6 | 0,9 | 1,4 | 6,3 - 7,9 | 7,98 | 24 | 79 |

| 1 x 4 | 56 x 0,30 | 3,2 | 1,0 | 1,5 | 7,2 - 9,0 | 4,95 | 38,4 | 100 |

| 1 x 16 | 84 x 0,30 | 3,9 | 1,0 | 1,6 | 7,9 - 9,8 | 3,30 | 57,6 | 135 |

| 1 x 10 | 80 x 0,40 | 5,1 | 1,2 | 1,8 | 9,5 - 11,9 | 1,91 | 96 | 204 |

| 1 x 16 | 128 x 0,40 | 6,3 | 1,2 | 1,9 | 10,8 - 13,4 | 1,21 | 153,6 | 286 |

| 1 x 25 | 200 x 0,40 | 7,8 | 1,4 | 2,0 | 12,7 - 15,8 | 0,780 | 240 | 390 |

| 1 x 35 | 280 x 0,40 | 9,2 | 1,4 | 2,2 | 14,3 - 17,9 | 0,554 | 336 | 523 |

| 1 x 50 | 400 x 0,40 | 11 | 1,6 | 2,4 | 16,5 - 20,6 | 0,386 | 480 | 699 |

| 1 x 70 | 356 x 0,50 | 13 | 1,6 | 2,6 | 18,6 - 23,3 | 0,272 | 672 | 950 |

| 1 x 95 | 485 x 0,50 | 15,1 | 1,8 | 2,8 | 20,8 - 26,0 | 0,206 | 912 | 1202 |

| 1 x 120 | 614 x 0,50 | 17 | 1,8 | 3,0 | 22,8 - 28,6 | 0,161 | 1152 | 1524 |

| 1 x 150 | 765 x 0,50 | 19 | 2,0 | 3,2 | 25,2 - 31,4 | 0,129 | 1440 | 1839 |

| 1 x 185 | 944 x 0,50 | 21 | 2,2 | 3,4 | 27,6 - 34,4 | 0,106 | 1776 | 2184 |

| 1 x 240 | 1225 x 0,50 | 24 | 2,4 | 3,5 | 30,6 - 38,3 | 0,0801 | 2304 | 2840 |

| 1 x 300 | 1530 x 0,50 | 27 | 2,6 | 3,6 | 33,5 - 41,9 | 0,0641 | 2880 | 3413 |

| 1 x 400 | 2034 x 0,50 | 31 | 2,8 | 3,8 | 37,4 - 46,8 | 0,0486 | 3840 | 4600 |

| 1 x 500 | 1768 x 0,60 | 35 | 3,0 | 4,0 | 41,3 - 52,0 | 0,0384 | 4800 | 6000 |

| 2 x 1 | 32 x 0,20 | 1,5 | 0,8 | 1,3 | 7,7 - 10,0 | 19,5 | 19,2 | 105 |

| 2 x 1,5 | 30 x 0,25 | 1,8 | 0,8 | 1,5 | 8,5 - 11,0 | 13,3 | 28,8 | 136 |

| 2 x 2,5 | 50 x 0,25 | 2,6 | 0,9 | 1,7 | 10,2 - 13,1 | 7,98 | 48 | 190 |

| 2 x 4 | 56 x 0,30 | 3,2 | 1,0 | 1,8 | 11,8 - 15,1 | 4,95 | 76,8 | 271 |

| 2 x 6 | 84 x 0,30 | 3,9 | 1,0 | 2,0 | 13,1 - 16,8 | 3,30 | 115,2 | 372 |

| 2 x 10 | 80 x 0,40 | 5,1 | 1,2 | - | 17,7 - 22,6 | 1,91 | 192 | 643 |

| 2 x 16 | 128 x 0,40 | 6,3 | 1,2 | - | 20,2 - 25,7 | 1,21 | 307,2 | 810 |

| 2 x 25 | 200 x 0,40 | 7,8 | 1,4 | - | 24,3 - 30,7 | 0,780 | 480 | 1160 |

| 3 G 1 | 32G0,20 | 1,5 | 0,8 | 1,4 | 8,3 - 10,7 | 19,5 | 28,8 | 125 |

| 3 G 1,5 | 30G0,25 | 1,8 | 0,8 | 1,6 | 9,2 - 11,9 | 13,3 | 43,2 | 162 |

| 3 G 2,5 | 50G0,25 | 2,6 | 0,9 | 1,8 | 10,9 - 14,0 | 7,98 | 72 | 229 |

| 3 G 4 | 56G0,30 | 3,2 | 1,0 | 1,9 | 12,7 - 16,2 | 4,95 | 115,2 | 329 |

| 3 G 6 | 84G0,30 | 3,9 | 1,0 | 2,1 | 14,1 - 18,0 | 3,30 | 172,8 | 452 |

| 3 G 10 | 80G0,40 | 5,1 | 1,2 | 3,3 | 19,1 - 24,2 | 1,91 | 288 | 776 |

| 3 G 16 | 128G0,40 | 6,3 | 1,2 | 3,5 | 21,8 - 27,6 | 1,21 | 460,8 | 1058 |

| 3 G 25 | 200G0,40 | 7,8 | 1,4 | 3,8 | 26,1 - 33,0 | 0,780 | 720 | 1473 |

| 3 G 35 | 280G0,40 | 9,2 | 1,4 | 4,1 | 29,3 - 37,1 | 0,554 | 1008 | 1728 |

| 3 G 50 | 400G0,40 | 11 | 1,6 | 4,5 | 34,1 - 42,9 | 0,386 | 1440 | 2302 |

| 3 G 70 | 356G0,50 | 13 | 1,6 | 4,8 | 38,4 - 48,3 | 0,272 | 2016 | 3400 |

| 3 G 95 | 485G0,50 | 15,1 | 1,8 | 5,3 | 43,3 - 54,0 | 0,206 | 2736 | 4450 |

| 3 G 120 | 614G0,50 | 17 | 1,8 | 5,6 | 47,4 - 60,0 | 0,161 | 3456 | 5180 |

| 3 G 150 | 765G0,50 | 19 | 2,0 | 6,0 | 52,0 - 66,0 | 0,129 | 4320 | 6500 |

| 4 G 1 | 32G0,20 | 1,5 | 0,8 | 1,5 | 9,2 - 11,9 | 19,5 | 38,4 | 163 |

| 4 G 1,5 | 30G0,25 | 1,8 | 0,8 | 1,7 | 10,2 - 13,1 | 13,3 | 57,6 | 197 |

| 4 G 2,5 | 50G0,25 | 2,6 | 0,9 | 1,9 | 12,1 - 15,5 | 7,98 | 96 | 279 |

| 4 G 4 | 56G0,30 | 3,2 | 1,0 | 2,0 | 14,0 - 17,9 | 4,95 | 153,6 | 402 |

| 4 G 6 | 84G0,30 | 3,9 | 1,0 | 2,3 | 15,7 - 20,0 | 3,30 | 230,4 | 561 |

| 4 G 10 | 80G0,40 | 5,1 | 1,2 | 3,4 | 20,9 - 26,5 | 1,91 | 384 | 935 |

| 4 G 16 | 128G0,40 | 6,3 | 1,2 | 3,6 | 23,8 - 30,1 | 1,21 | 614,4 | 1286 |

| 4 G 25 | 200G0,40 | 7,8 | 1,4 | 4,1 | 28,9 - 36,6 | 0,780 | 960 | 1692 |

| 4 G 35 | 280G0,40 | 9,2 | 1,4 | 4,4 | 32,5 - 41,1 | 0,554 | 1344 | 2266 |

| 4 G 50 | 400G0,40 | 11 | 1,6 | 4,8 | 37,7 - 47,5 | 0,386 | 1920 | 3021 |

| 4 G 70 | 356G0,50 | 13,1 | 1,6 | 5,2 | 42,7 - 54,0 | 0,272 | 2688 | 4121 |

| 4 G 95 | 485G0,50 | 15,1 | 1,8 | 5,9 | 48,4 - 61,0 | 0,206 | 3648 | 5361 |

| 4 G 120 | 614G0,50 | 17 | 1,8 | 6,0 | 53,0 - 66,0 | 0,161 | 4608 | 6546 |

| 4 G 150 | 765G0,50 | 19 | 2,0 | 6,5 | 58,0 - 73,0 | 0,129 | 5760 | 8095 |

| 4 G 185 | 944G0,50 | 21 | 2,2 | 7,0 | 64,0 - 80,0 | 0,106 | 7104 | 9652 |

| 4 G 240 | 1225G0,50 | 24 | 2,4 | 72,0 - 91,0 | 0,0801 | 9216 | 12614 | |

| 4 G 300 | 1530G0,50 | 27 | 2,6 | 80,0 - 101 | 0,0641 | 11520 | 15200 | |

| 5 G 1 | 32 x 0,20 | 1,5 | 0,8 | 1,6 | 11,6 | 19,5 | 48 | 168 |

| 5 G 1,5 | 30 x 0,25 | 1,8 | 0,8 | 1,8 | 11,2 - 14,4 | 13,3 | 72 | 234 |

| 5 G 2,5 | 50 x 0,25 | 2,6 | 0,9 | 2,0 | 13,3 - 17,0 | 7,98 | 120 | 348 |

| 5 G 4 | 56 x 0,30 | 3,2 | 1,0 | 2,2 | 15,6 - 19,9 | 4,95 | 192 | 470 |

| 5 G 6 | 84 x 0,30 | 3,9 | 1,0 | 2,5 | 17,5 - 22,2 | 3,30 | 288 | 620 |

| 5 G 10 | 80 x 0,40 | 5,1 | 1,2 | 3,6 | 22,9 - 29,1 | 1,91 | 480 | 1155 |

| 5 G 16 | 128 x 0,40 | 6,3 | 1,2 | 3,9 | 26,4 - 33,3 | 1,21 | 768 | 1460 |

| 5 G 25 | 200 x 0,40 | 7,8 | 1,4 | 4,4 | 32,0 - 40,4 | 0,780 | 1200 | 2380 |

| 5 G 35 | 280 x 0,40 | 9,2 | 1,4 | 4,5 | 37 - 42 | 0,554 | 1680 | 2716 |

| 5 G 50 | 400 x 0,40 | 11 | 1,6 | 5,0 | 43 - 47 | 0,386 | 2400 | 3809 |

| 5 G 70 | 356 x 0,50 | 13,1 | 1,6 | 5,5 | 45 - 50 | 0,272 | 3360 | 5087 |

| 7 G 1,5 | 30 x 0,25 | 1,8 | 0,8 | 2,5 | 14 - 15,7 | 13,3 | 100,8 | 335 |

| 12 G 1,5 | 30 x 0,25 | 1,8 | 0,8 | 2,9 | 17,6 - 22,4 | 13,3 | 172,8 | 560 |

| 19 G 1,5 | 30 x 0,25 | 1,8 | 0,8 | 2,5 | 22,5 - 26,6 | 13,3 | 273,6 | 795 |

| 24 G 1,5 | 30 x 0,25 | 1,8 | 0,8 | 3,5 | 24,3 - 30,7 | 13,3 | 345,6 | 1000 |

| 36 G 1,5 | 30 x 0,25 | 1,8 | 0,8 | 3,8 | 33,0 | 13,3 | 518,4 | |

| 7 G 2,5 | 50 x 0,25 | 2,6 | 0,9 | 2,7 | 16,5 - 18,2 | 7,98 | 168 | 520 |

| 12 G 2,5 | 50 x 0,25 | 2,6 | 0,9 | 3,1 | 18,5 - 22,5 | 7,98 | 288 | 760 |

| 19 G 2,5 | 50 x 0,25 | 2,6 | 0,9 | 3,5 | 24,6 - 31 | 7,98 | 456 | 1075 |

| 24 G 2,5 | 50 x 0,25 | 2,6 | 0,9 | 3,9 | 28,8 - 36,4 | 7,98 | 576 | 1390 |

| 36 G 2,5 | 50 x 0,25 | 2,6 | 0,9 | 4,3 | 37,5 | 7,98 | 864 | |

Application:

Multicore High Flexible Cable, used for easy-duty and medium mechanical loads in dry areas. Suitable for household, kitchens, offices and workshops (for inst. tailoring) for smaller electrical devices (washing-machines, vacuum-cleaners, irons, household appliances, soldering sets etc.) and mobile devices operating in heavier conditions, such as light industrial and agricultural machines.

Multicore Solid Cable

|

| Description | Multicore Solid Cable |

| Conductor | 1/2 Bare Copper Conductor(Solid) |

| Insulation | PVC Compound |

| Color | Red, Blue, Grey, Yellow/Green or as request |

| Sheath | PVC Compound |

| Sheath Color | White, Black, Grey |

| Temperature Range | -30 - 70ºC |

| Nominal Voltage | 300/500V, 450/750 V |

| Test Voltage | 2000 V |

| Minimal Bending Radius | 6D |

| Standard | IEC 60227, JB8734.2 |

| Cores x conductor cross-section | Conductor construction | External diameter | Conductor resistance at 20 °C | Insulation resistance at 70 °C | Short circuit current 1s | Permited tensile load | Cable weight |

| nominal | min-max. | max. | min. | nominal | max. | cca | |

| mm² | n x mm | mm | Ω/km | MΩkm | kA | N | kg/km |

| 1 x 1,5 | 1 x 1,38 | 5,2 - 6,2 | 12,10 | 0,0100 | 0,17 | 75 | 45 |

| 1 x 2,5 | 1 x 1,78 | 5,8 - 6,8 | 7,41 | 0,0094 | 0,29 | 125 | 70 |

| 1 x 4 | 1 x 2,26 | 6,4 - 7,6 | 4,61 | 0,0087 | 0,46 | 200 | 80 |

| 1 x 6 | 1 x 2,70 | 6,8 - 8,2 | 3,08 | 0,0074 | 0,69 | 300 | 105 |

| 1 x 10 | 1 x 3,5 | 8,0 - 9,4 | 1,83 | 0,0072 | 1,15 | 500 | 155 |

| 1 x 16 | 7 x 1,70 | 9,4 - 11,0 | 1,15 | 0,0053 | 1,84 | 800 | 230 |

| 1 x 25 | 7 x 2,13 | 12,2 - 13,3 | 0,73 | 0,0051 | 2,88 | 1250 | 325 |

| 2 x 1,5 | 1 x 1,38 | 8,4 - 9,8 | 12,10 | 0,0100 | 0,17 | 150 | 115 |

| 2 x 2,5 | 1 x 1,78 | 9,6 - 11,0 | 7,41 | 0,0094 | 0,29 | 250 | 190 |

| 2 x 4 | 1 x 2,26 | 11,0 - 12,5 | 4,61 | 0,0087 | 0,46 | 400 | - |

| 3 x 1,5 | 1 x 1,38 | 8,8 - 10,5 | 12,10 | 0,0100 | 0,17 | 225 | 135 |

| 3 x 2,5 | 1 x 1,78 | 10,0 - 11,5 | 7,41 | 0,0094 | 0,29 | 375 | 190 |

| 3 x 4 | 1 x 2,26 | 11,5 - 13,0 | 4,61 | 0,0087 | 0,46 | 600 | 265 |

| 3 x 6 | 1 x 2,70 | 12,0 - 15,0 | 3,08 | 0,0074 | 0,69 | 900 | 315 |

| 3 x 10 | 1 x 3,5 | 16,0 - 18,0 | 1,83 | 0,0072 | 1,15 | 1500 | 465 |

| 4 x 1,5 | 1 x 1,38 | 9,5 - 11,0 | 12,10 | 0,0100 | 0,17 | 300 | 160 |

| 4 x 2,5 | 1 x 1,78 | 11,0 - 12,5 | 7,41 | 0,0094 | 0,29 | 500 | 230 |

| 4 x 4 | 1 x 2,26 | 12,5 - 14,5 | 4,61 | 0,0087 | 0,46 | 800 | 330 |

| 4 x 6 | 1 x 2,70 | 14,5 - 16,5 | 3,08 | 0,0074 | 0,69 | 1200 | 460 |

| 4 x 10 | 1 x 3,5 | 16,5 - 19,0 | 1,83 | 0,0072 | 1,15 | 2000 | 690 |

| 4 x 16 | 7 x 1,70 | 20,5 - 23,5 | 1,15 | 0,0053 | 1,84 | 3200 | 1090 |

| 4 x 25 | 7 x 2,13 | 25,0 - 28,5 | 0,73 | 0,0051 | 2,88 | 5000 | 1640 |

| 4 x 35 | 7 x 2,52 | 27,5 - 32,0 | 0,52 | 0,0045 | 4,02 | 7000 | 2090 |

| 5 x 1,5 | 1 x 1,38 | 9,9 - 12,0 | 12,10 | 0,0100 | 0,17 | 375 | 190 |

| 5 x 2,5 | 1 x 1,78 | 11,5 - 13,5 | 7,41 | 0,0094 | 0,29 | 625 | 270 |

| 5 x 4 | 1 x 2,26 | 14,0 - 16,5 | 4,61 | 0,0087 | 0,46 | 1000 | 410 |

| 5 x 6 | 1 x 2,70 | 15,5 - 18,0 | 3,08 | 0,0074 | 0,69 | 1500 | 540 |

| 5 x 10 | 1 x 3,5 | 18,0 - 21,0 | 1,83 | 0,0072 | 1,15 | 2500 | 850 |

| 5 x 10 | 7 x 1,35 | 18,5 - 21,5 | 1,83 | 0,0065 | 1,15 | 2500 | 870 |

| 5 x 16 | 7 x 1,70 | 22,5 - 26,0 | 1,15 | 0,0053 | 1,84 | 4000 | 1350 |

| 5 x 25 | 7 x 2,13 | 27,5 - 31,5 | 0,73 | 0,0051 | 2,88 | 6250 | 1990 |

| 7 x 1,5 | 1 x 1,38 | 11,0 - 13,0 | 12,10 | 0,0100 | 0,17 | 525 | 235 |

| 10 x 1,5 | 1 x 1,38 | 13,9 - 15,6 | 12,10 | 0,0100 | 0,17 | 750 | 330 |

| 12 x 1,5 | 1 x 1,38 | 14,2 - 16,1 | 12,10 | 0,0100 | 0,17 | 900 | 400 |

| 7 x 2,5 | 1 x 1,78 | 12,7 -14,3 | 7,41 | 0,0094 | 0,29 | 875 | 350 |

Installation cable suitable for household and industrial usage. Laid on or under plaster, in walls or concrete, without special mechanical protection, but not in dry or pre-stressed concrete. Suitable for dry, same as damp or wet environment; for internal or external application (only if the cable is protected against direct sunlight).

Flexible Unshielded Cable

|

| Description | Multi-core flexible unshielded cable |

| conductor: | 5/6 grade stranded copper wire (flexible) |

| insulation: | PVC Compound |

| Insulation color | Red, blue, gray, yellow/green or on request |

| sheath | PVC compound |

| Sheath color | White, black |

| temperature range | -30 - 70ºC |

| Rated Voltage | 300 / 500V,450 / 750V |

| Test voltage | 2000 V |

| Minimum bending radius | 4D for D <8mm 5D for 8-12mm 6D for D> 12 |

| Standard | IEC 60552 |

| Core x conductorCross section | Conductor structure | Outer diameter | Insulation thickness | Sheath thickness | Conductor resistance at 20 ° C | Insulation resistance at 70 ° C | Copper weight | Cable weight |

| Nominal | min-max. | Nominal | Nominal | max | minute. | |||

| mm² | nx mmmm | mm | mm | mm | Ω/kg | MΩkm | kg/km | kg/km |

| 2 x 0,75 | 24 x 0,20 | 5,7 - 07,2 | 0,6 | 0,8 | 26,0 | 0.011 | 14,4 | 52 |

| 2 x 1 | 32 x 0,20 | 5,9 - 07,5 | 0,6 | 0,8 | 19,5 | 0.010 | 19,2 | 65 |

| 2 x 1,5 | 30 x 0,25 | 6,8 - 08,6 | 0,7 | 0,8 | 13,3 | 0.010 | 28,8 | 90 |

| 2 x 2,5 | 50 x 0,25 | 8,4 - 10,6 | 0,8 | 1,0 | 7,98 | 0,0095 | 48,0 | 115 |

| 3G0,75 | 24 x 0,20 | 6,0 - 07,6 | 0,6 | 0,8 | 26,0 | 0,011 | 21,6 | 70 |

| 3G1 | 32 x 0,20 | 6,3 - 08,0 | 0,6 | 0,8 | 19,5 | 0,010 | 28,8 | 80 |

| 3G1,5 | 30 x 0,25 | 7,4 - 09,4 | 0,7 | 0,9 | 13,3 | 0,010 | 43,2 | 115 |

| 3G2,5 | 50 x 0,25 | 9,2 - 11,4 | 0,8 | 1,1 | 7,98 | 0,0095 | 72,0 | 175 |

| 3G4 | 56 x 0,30 | 10,5 - 13,1 | 0,8 | 1,2 | 4,95 | 0,0078 | 115,2 | 235 |

| 4G0,75 | 24 x 0,20 | 6,6 - 08,3 | 0,6 | 0,8 | 26,0 | 0,011 | 28,8 | 75 |

| 4G1 | 32 x 0,20 | 7,1 - 09,0 | 0,6 | 0,9 | 19,5 | 0,010 | 38,4 | 92 |

| 4G1,5 | 30 x 0,25 | 8,4 - 10,5 | 0,7 | 1,0 | 13,3 | 0,010 | 57,6 | 145 |

| 4G2,5 | 50 x 0,25 | 10,1 - 12,5 | 0,8 | 1,1 | 7,98 | 0,0095 | 96,0 | 210 |

| 4G4 | 56 x 0,30 | 11,5 - 14,3 | 0,8 | 1,2 | 4,95 | 0,0078 | 153,6 | 299 |

| 4G6 | 84 x 0,30 | 14,7 | - | - | 3,30 | 0,0068 | 230,4 | 480 |

| 5G0,75 | 24 x 0,20 | 7,4 - 9,3 | 0,6 | 0,9 | 26,0 | 0,011 | 36,0 | 96 |

| 5G1 | 32 x 0,20 | 7,8 - 9,8 | 0,6 | 0,9 | 19,5 | 0,010 | 48,0 | 113 |

| 5G1,5 | 30 x 0,25 | 9,3 - 11,6 | 0,7 | 1,1 | 13,3 | 0,010 | 72,0 | 175 |

| 5G2,5 | 50 x 0,25 | 11,2 - 13,9 | 0,8 | 1,2 | 7,98 | 0,0095 | 120,0 | 260 |

| 5G4 | 56 x 0,30 | 13,0 - 16,1 | 0,8 | 1,4 | 4,95 | 0,0078 | 192,0 | 363 |

| 5G6 | 84 x 0,30 | 16,7 | - | - | 3,30 | 0,0068 | 288,0 | 583 |

| 7G1 | 32 x 0,20 | 09,0 | 0,6 | - | 19,5 | 0,010 | 67,2 | 136 |

| 7G1,5 | 30 x 0,25 | 10,6 | 0,7 | - | 13,3 | 0,010 | 100,8 | 195 |

| 7G2,5 | 50 x 0,25 | 13,0 | 0,8 | - | 7,98 | 0,0095 | 168,0 | 294 |

This product is suitable to be used in household appliances such as washing machines, spin dryers and refrigerators, electric tools and lighting in home , office and similar indoor place where need flexible wire.

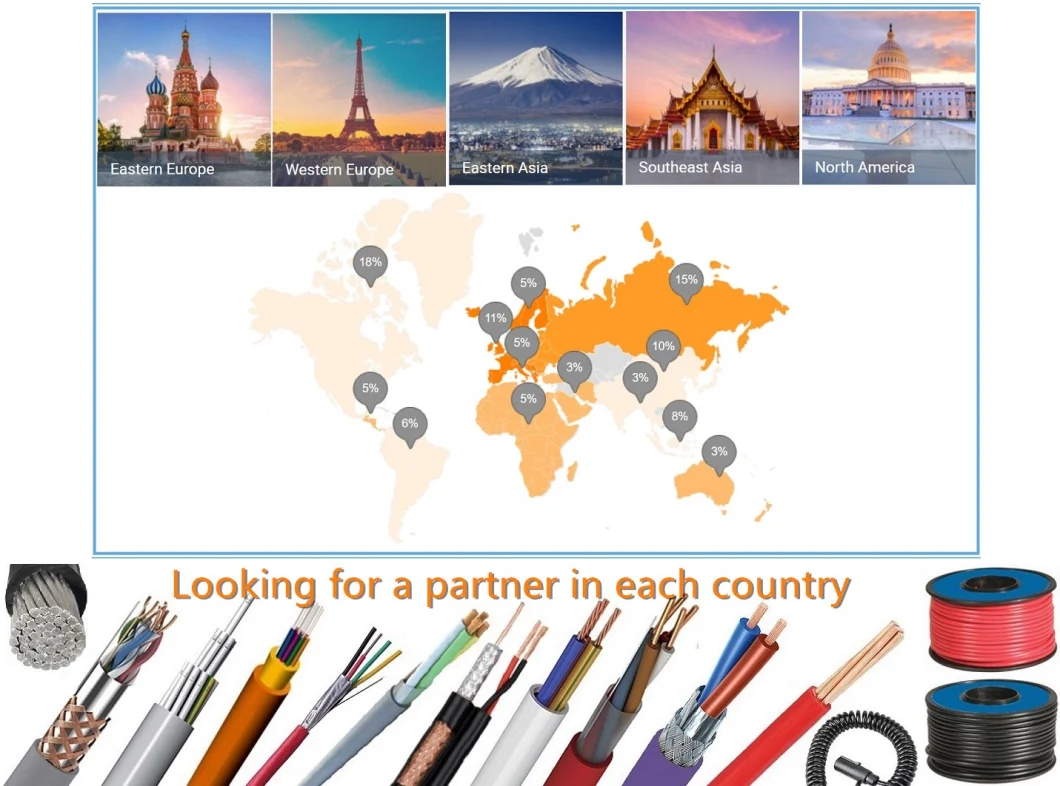

| SUZHOU DESAN WIRE CO. Ltd., established in 2017, is a leading professional developer, designer, manufacturer and supplier of industrial wire, service wire, flexible wire, aluminum cable, communication cable, computer cable, construction cable, high temperature cable, high frequency wires and cables, special cable, spring spiral cable, connectors, etc. Our high frequency cables include HDMI, USD3.0, USB3.1, display port, lightning, mini SAS, QSFP, MHL series, etc. We focus on providing high quality OEM/ODM products and services to clients all over the world. To maintain our high quality standards, we use high-tech equipments, meanwhile upgrade the equipments and quality control procedures annually. Our products are produced in accordance with CE, RoHS, REACH and have already passed UL, ETL, CPR, ISO9001, ISO14001. We give response to clients quickly since we have a strong energetic and dynamic team. Our products are used widely in mobile phone, digital TV, digital products for cars, portable digital products, computer peripherals, large intelligent heavy industrial equipment, intelligent robots, advanced medical equipments, LED screen, LED lighting, audio visual equipments, stage lighting, industrial automation equipments, construction projects, homes, etc. "Quality first, service first, continuous improvement and innovation to meet the customers" is our principle. We sincerely hope to establish long friendly business relationship with clients from all over the world. Our goal is not just providing perfect product, but also providing a complete solution for our customers to achieve their upmost satisfaction We aim to create more innovative products with more sustainable materials and newer technologies Offering the excellent quality with the most superior services is always our pursuit. ********************************************************************************************** STRICT QUALITY CONTROL: Suzhou Desan Wire Co., Ltd. Pays high attention to our product quality control from incoming raw materials to finished products. Our staff in Quality Control Department not only execute strict QC rules during cable production, but also train staff and help them understand the importance of QC before they work on production lines. To meet our customers' quality standards our Quality Control Department is well equipped with all kinds of inspection testers such as SIKORA curing optimization software, partial discharge detector, cross section projector, tensile machine, flame tester, aging box, winding tester, resistivity tester and so on. ********************************************************************************************* COMPANY CULTURE: Enterprise Spirit: Self-discipline and social commitment, diligent courage and intelligent tactics Enterprise Characteristic or Style: Rapid response, Quick action. |

Testing Equipments:

1. Q: Are you a factory or a trading company?

A: We are a factory with more than 10 years' manufacturing experience.2. Q: What standard of your products?

A: We will manufacture according to your required standard.

3. Q: Where is your factory located?

A: 4# Chuangxin Middle Road, Yinghu Industrial Park, Wangting Town, Xiangcheng Distric, Suzhou City, P. R. China, Suzhou, Jiangsu, China

4. Q: How can I get some samples?

A: If we have in stock, within 10 meters, it is free. Otherwise we will charge sample fee.

5. Q: Are samples free shipping?

A: Sorry, it should be on your side.

6: Q: What is your payment term?

A: We have several payment terms for you, T/T, Western Union, etc.

7: Q: What about the lead time for mass production?

A: Frankly speaking, it depends on the order quantity and the seasons.

8: Q: Do you have the mentioned wire in stock?

A: After knowing what you need, we will check with our warehouse. If your order quantity reaches 6800m/size/color can arrange production.

Key Words:

Multicore High Flexible Cable

Multicore Solid Cable

Flexible Unshielded Cable

Multicore PVC Cable